|

Photo #1: This is one of several movable supports on Don Mentzer's trailer for IdlTime. I suspect that the contour of a lifeboat hull means that its attitude on the trailer can vary and that two fore and two aft adjusters compensate for this, so that it always sits square.

|

|

|

Photo #2: The joys of an open crankcase: I now use the largest model feedpump sold by Coles Power Models, to siphon slop from the oil pan into a "holding tank", to prevent stuff flying all over the boat. At day's end, the goo is poured into a plastic soda bottle where the oil and water can separate. Once the water is removed, the sludge goes to the recycling center back home.

|

|

|

Photo #3: Many folks admired my new digital tachometer, conceived of by my friend Bryan Mumford. Its location is temporary until I find a place where it can be easily viewed. For now it is attached to my portside control panel with 2 strips of Velcro. In this way, I can rip it free to read it better when the situation warrants. If you think you want one, email me: I'm compiling a list and when I get ten or so I'll whack them out.

|

|

|

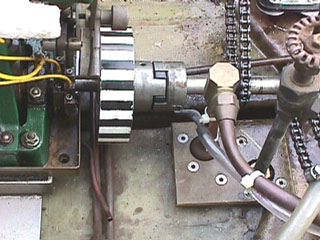

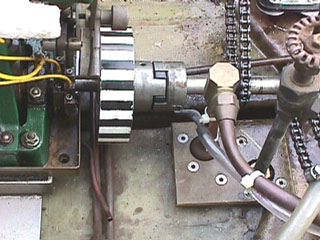

Photo #4: Here's the sensor which detects a rotating magnet as it sweeps past. The magnet is a little 3/8" dia. button job that is epoxied into a drilled recess in the fattest part of my Lovejoy coupling. I fastened the wiring to the coldest pipe in the boat, the river water siphon tube, which is conveniently close.

|

|

|

Photo #5: Andy Philbrick has much less of an oil slopping problem with his single-acting enclosed crankcase engine. He uses this neat little bilge pump and hanging can arrangement to deal with it.

|

|

|

Photo #6: Here's a shot of the engineer's station aboard Andy's boat. He has arranged the damper door control so that it may be adjusted from the standing position, using a long rod and locking knob. Note the simple red-handled throttle on the main steam line.

|

|

|

Photo #7: This swivelling automotive mirror lets Andy see what the burner is doing without stooping.

|

|

|

Photo #8: This incredible confabulation is John Noble's iteration of the venerable "Windemere Kettle". He's silver soldered two or three turns of copper tube to the bottom of a coffee pot.

|

|

|

Photo #9: Coffee, anyone? John says he can fill the pot with cold water and have it boiling in 2 minutes, 50 seconds!

|

|

|

Photo #10: Gerry Blaine's (or is this Bud Leutza's??) exquisit Steeple compound engine.

|

|

|

Photo #11: The infamous Mudlump Detector. This contraption is a perpetual trophy and it is the duty of each year's winner to add another useful appliance to it. It is now so sophisticated that it defies analysis.

|

|

|

Photo #12: Not the greatest photo, but The vertical connecting rod that joins camshaft to bellcrank on Bart Smaalders' engine broke on the threaded portion. He fixed this by first holding the broken halves together, then threading a nut over the intersection. With this temporary bandage, he silver soldered it whole once more. Well, it lasted for a while! Bart has written a thorough account in Ripping Yarns.

|

|