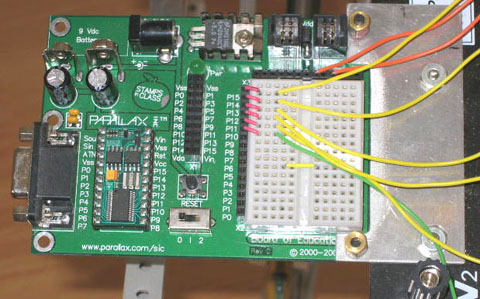

As of today I've gotten Patty O'Furniture to the point where it will, indeed, do a few programmed dance steps. CO-2 consumption is low enough that the thing could probably dance for hours on end before I'd need to replace tanks, too. In order to quickly enter longer dance programs I've ordered a Matrix Keypad and MEMKey from Parallax. These will allow me to assign each solenoid movement program to a specific key. Since I've succeded in blowing out half of its output pins I've also ordered the Opto22 8-Channel I/O Module Rack and assorted tackle to provide opto-isolation of the BS-2 chip, heh. This will be particularly useful as I begin the transition to stepper motor control of advanced leg designs and other non-Patty projects I have in mind.

I've come to the conclusion that the current hardware configuration is not optimal; i.e. it will be necessary for the legs to be more human-like in form, to optimize transfer of tap dance notation directly into the device. Without this hardware transformation I'm going to get quickly bogged down in the business of interpretation; i.e. exchanging one movement that makes sense for another that only sort of makes sense.

It wasn't a princely sum; in total I've spent a little over $400 to implement these upgrades; not bad as artsy-fartsy hacks go I guess... Goodbye Miller Dynasty 200; maybe next year.

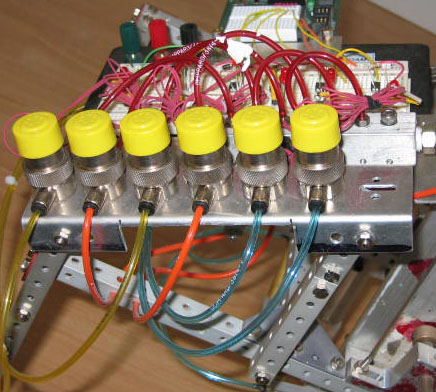

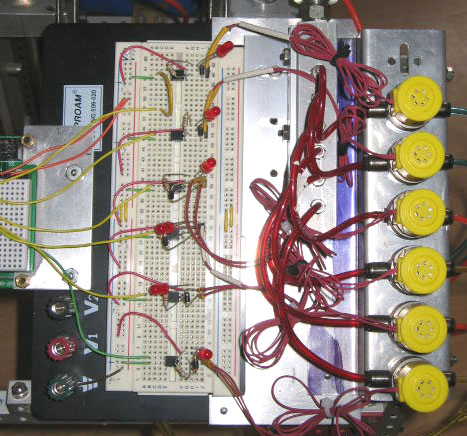

Following are photos of the current iteration. I'll continue using the legs in their present form until I've mastered the new Parallax mods. Once that's done (Help! Help! My extremely kewl UC Extension class "Gizmology " has been cancelled!) I'll head back to the shop and start on more anthropomorphic legs.