Progress on fireball shooters is slow but steady. I've been sidetracked by a couple of production jobs that will hopefully generate a little income to pay for this or that extravagant hobby of mine. At the last Burning Silicon Collective meeting I attended I finally discovered that Bonefire Bob Hoffman, the expert everyone raves about, has a website up where he sells some really beautiful (but expensive!) fireball shooters, all assembled and ready to go. In my quest to save a few bucks I've been trying to find the necessary kit to do my own low-ball contraptions.

The latest find involves the cauldrons, i.e. the fireball exit nozzles, which have to be shaped juuuust right: from conversations with various fireball shooter builders it seems the best shape is a sort of wine-glass with the top lip curving in from parallel towards the top lip. I suppose it would be possible, after much trial and error, to spin my own on the lathe, but I sensed that something from the "real world" had a very close shape to this and could be hacked. After a few fruitless leads and a couple of dead-end trips to various stores I struck gold at a restaurant supply house. Gotta go back and get more in a few weeks; they only had three and I need four; a few spares would be even better.

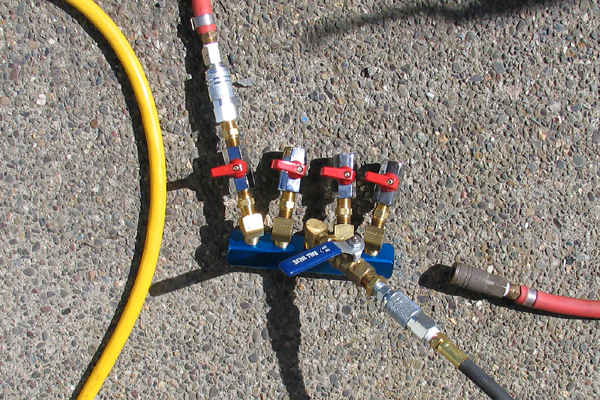

April 29: During the rains I did find a steady source for the milk dispensers; they're a standard item at, of all places, Bed, Bath & Beyond and they didn't cost any more than the ones I got from the second hand restaurant supply place.The rains finally abated last week and I'm back to doing stuff in a no-longer damp and freezing shop. I've finally assembled all of the components to put one fireball shooter together. It ain't elegant, which is to say, although I've got everything I need to try it out, it's not in what I would call the preferred embodiment. I'll be able to do the first full power test after the sun goes down tonight.

Return to the Art Car Project

Return to Steamboat Ed Haas

Please send feedback to: "Steamboat Ed" Haas